Before we begin…

I wanted this blog post to be a little bit different. My high school has jumped headlong into creating a makerspace, going so far as to rip out our old auto shop and buy ten 3D printers, soldering stations, and drones. My school division has essentially pulled out most of the stops (more on that later) to create a program around this idea. As such I took an hour after school to talk with the head of our program (let’s call him “Tim”) and asked him to speak to some of the challenges of running a course based on these principles.

But before that I would like to emphasize a point Gilles made in our breakout room: makerspaces are not necessarily high tech. As others have emphasized makerspaces are about building community through the sharing of tools, talent, and materials. The materials required can be as simple as Lego blocks, paper, and clay. As Becker (2019) emphasized this is about creating a culture of design and problem solving utilizing whatever tools and materials are available. Further to this Gilles echoed Becker’s sentiment about the value of seeing students in a context other than the traditional classroom; students who are unmotivated become interested and engaged when challenged with hands on activities. Makerspaces allow us to see our students in a different light.

Furthermore, the act of creation is engaging. The highest praise I can give to this week’s presentation was that it went quickly because I was really enjoying it. In my breakout group I was tasked with creating a vessel that would hold water. I had at my disposal paper, straws, and masking tape.

Behold the results:

Success!

Designing is fun and educational regardless of the age of the participant. As a middle aged man I am loathe to admit that I missed some of the slides in this week’s PowerPoint because I was busing perfecting my paper container.

The Value of Having a Makerspace at My School

One of my math students was speaking to her homeroom teacher about her favourite class, the makerspace. Her family came to Canada from Vietnam to offer their daughter a better education. The student was delighted that she was engaging in “hands on learning” and was getting the kind of classroom experiences her parents had hoped for.

This illustrates what Tim is seeing within the broader program. Students enjoy the process of problem solving and applying the principles they learn in math and physics while working towards a tangible goal. In Tim’s words the students are constantly engaging in “design thinking” and learning skills that are in demand in the commercial space. This echoes Meenu’s observation that this type of learning is not only enjoyable and challenging, but has the potential to lift students up socially by giving them the skills to enter high paying careers.

Below is a picture of some “robot flowers” our students created using photo sensitive triggers and motors that open their petals when a light shines on them.

Who Benefits

It was surprising to hear that the students who were experiencing success in our makerspace were not the “usual suspects” (the academically inclined students). As Tim described it isn’t always the star pupils who thrive in design classes. For example he noticed that the students who are distracted by their cellphones during his psychology class (like all teachers he is forced to wear many hats) hardly check them when they are creating 3D models in Tinkercad. On the downside he has observed some students dismiss the makerspace, particularly those with low socioeconomic status, as the school system has disenfranchised and discriminated against them their whole lives. Some of these students see technology as the domain of the rich and privileged and as a result don’t try in the class (he referred to this as a “self fulfilling prophecy”).

The Obstacles Holding Us Back

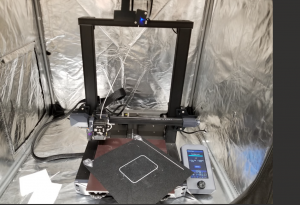

Despite what Becker (2019) claims in her article 3D printing can be quite challenging (to be fair her 3D printing was handled by the University of Calgary so she was insulted from any issues). In addition, not all makerspaces include a 3D printing component, but at my school it is integral to our program. One of the difficulties we face is the number of printers we have versus the amount of work they can perform. As Tim indicated a small printing job may take 3 to 5 hours, and larger jobs upwards of an entire day (the amount of time a print job takes depends on factors including quality, complexity, and size). With 28 students and 10 printers one set of class projects could take days, if not weeks to build. It also bears noting that the printers cannot run 24 hours a day unsupervised as printing errors are quite common. This creates classroom management challenges; teachers need to be constantly planning their classes to accomodate students who are waiting for components to be fabricated.

In addition to the challenges of time our machines need maintenance including calibration. As Tim noted most commercial printing farms have 130% capacity to account for machines breaking down.

What it is like teaching in a Makerspace, and the need for technological savvy

Low tech makerspaces aren’t the exclusive domain of the tech enthusiast. As our presenters demonstrated prototyping and constructing objects can be done with any materials with a bit of imagination. However when you move into the high tech sphere technological savvy and know how become critical. As Tim told me it is not enough for a teacher to be technologically literate, instead they need to be willing to work within a community. As he pointed out a lot of the technologies we are employing in our school are community driven, not manufacturuer driven. For example our 3D printers are currently utilizing firmware (the embedded electronic instructions that make the hardware function) that was recommended by a facebook group that he participates in. Often difficulties arise that require him to seek answers from his peers and friends; isolationists do not fare well in the makerspace. In addition it essential that the teacher in a high tech makerspace have at least a passing familiarity with electronics. Tim indicated that those getting into this space be comfortable with high current electronics, soldering, and troubleshooting components with a multimeter. Does this make this the exclusive domain of the “techie” individual? Not really, but the school division and its tech services were not able to troubleshoot his hardware when it initially didn’t work. Learning these types of skills aren’t neccessarily straightforward either, he acquired his know how through several years of trial and error working with 3D printing and electronics on his own. He recommended anyone getting into 3D printing should check out Teaching Tech on YouTube, (and its associated Github) which has been an invaluable resource.

It is interesting to see the subject of our class discussions coming alive before my eyes. Next semester we will be expanding the scope of it to encompass more grades and more in depth projects.

Hi Matt,

That looks like a really impressive set up that “Tim” has at your school. I remember doing my internship at Campbell and during those months the school got its first 3D printer. (I wonder how many they have now?) I remember students were amazed they could make phone cases and I asked if a student could make me one and she said it would take about 3 days for it to fully print. 3 days?!? I think the printers are more advanced and it would no longer take 3 days for that small of a print. My current school has one printer and it is an older model. I know our computer science teacher uses it to make some pretty cool things, but we do lack a teacher or advocate in the building for these programs. We have a relatively new teacher to our school, I’ll call her “Anne”. Anne has a bit of a robotics background, but our students could benefit from someone with an extensive background or someone who is truly passionate about the topic.

Matt – great post and nice water holding contraption! We were lucking enough to have access to use some 3D printers last year with some 7s & 8s (my first time using them) where I was completely blown away by the engagement and knowledge that these kids already had. I had missed some instructions from our lead (dealing with hotspots in the class) so I had to call on the help of some students who knew what they were doing and did they make me feel very inept when it came to technology! The students in “Tim’s” class really are lucky to have that type of space to learn and create!

Impressed by the work you did prior to the presentation – like you, I would of been going into that class with such limited knowledge of the two distinct topics. What an incredible set-up your colleague has at Johnson. I never considered things like “time” to print as being a factor but it certainly would be. Your mention of maintenance of the technology is also a point to consider when you using tech in a lab like setting as you have described.

I appreciated the mention of building community through makerspaces. How some students become more engaged in their learning when allowed to explore and create. My school has a fantastic low-tech makerspace set up in a Multipurpose room in the basement. They had it set up at the beginning of 2020 with quite a bit of funds dedicated to making it a reality. When talking with some teachers who have been there since its creation, COVID definitely derailed their plans for the space. It has not really been utilized since its creation (which happened right before the world shut down). The other barrier is its location. It’s not in a place that is visible so that teachers remember that it exists. The room is literally tucked away in the basement where nobody ever goes. My goal for this year is to use the space and try to re-engage the school (or initiate it because it wasn’t really used yet) to see the benefits of having a dedicated space.